TelMA Torque offers predictive maintencance, data for machine control and condition monitoring for any aggregates (gearboxes, motors, pumps, generators, agricultural vehicles, etc.) as a cost-effective, dynamic torque acquisition and thus offers you the possibility to further develop your product Industry 4.0.

Is not an OEM product, but a universal solution that offers the tool Industry 4.0 and new competitive advantages to German mechanical engineering. Be part of it!

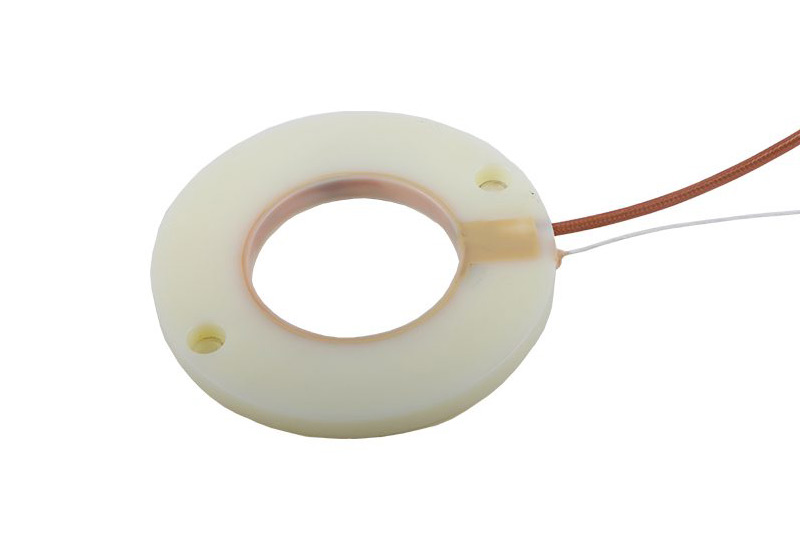

The proven properties of strain gauge technology and near-field telemetry are combined with a cost-effective application technology to create a torsion sensor in postage stamp format. The postage stamp format makes the solution suitable both for new designs and for integration into existing systems (retro-fit).

The basic prerequisite Industry 4.0 is the recording of physical variables on the machines. This is the only way to achieve concepts such as predictive maintenance with lower maintenance costs, shorter downtimes and improved energy efficiency. The determination of load spectra also enables an improved design of gearboxes, as well as predictions about the remaining service life.

The most important variable is torque. Previous solutions for torque measurement in series production gearboxes Industry 4.0 are not considered economically feasible and not robust enough. This was due on the one hand to excessively high acquisition costs and on the other hand to the required know-how in the application and use of the measurement technology.

The new TelMA Torque miniaturised telemetric sensor, for which a patent application has already been pending, is designed to eliminate precisely these disadvantages. The sensor is applied using micro-welding technology. The micro-welding technique is particularly suitable here because there are no structural changes and the strength of the shaft does not suffer. No soldering iron or failure-prone gluing process is required for mounting.