For the vehicle sector, the Co2 discussions are demanding ever higher requirements in terms of accuracy and resolution of the torque measurement signal. For further optimization of the efficiency, the accuracy of the dynamic torque measurement is of fundamental importance.

MANNER’s answer is the new XtreMA-high precision product series.

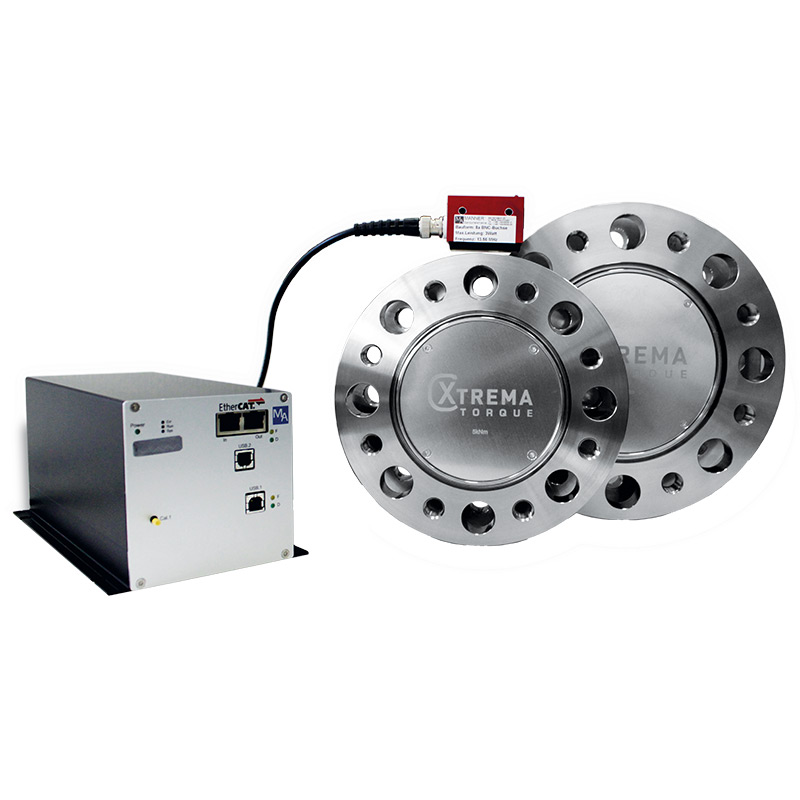

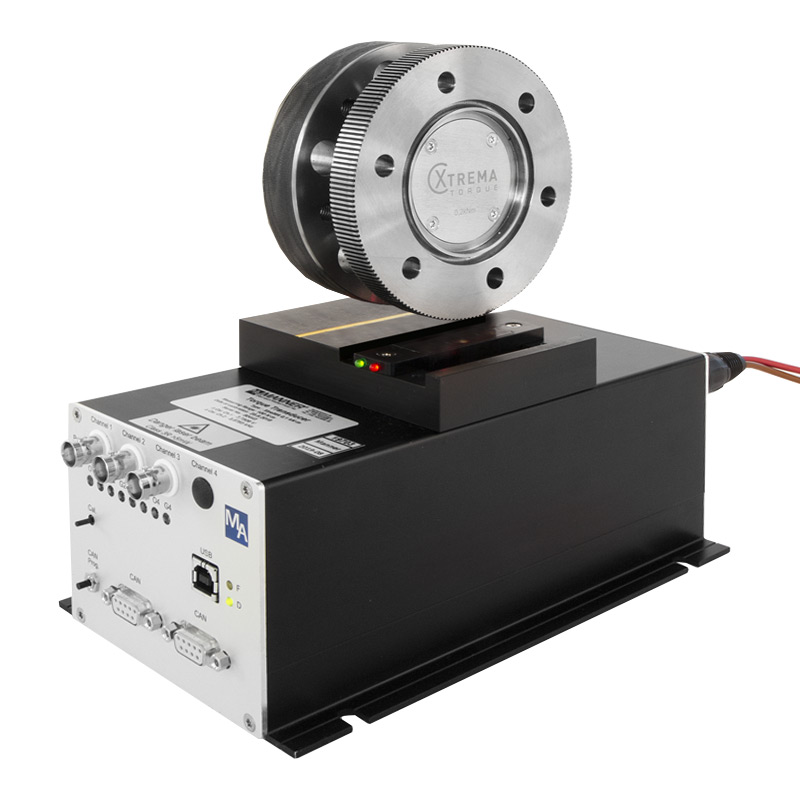

The new XtreMA-high precision series of measuring flanges from MANNER Sensortelemetrie offers not only an attractive price but also the typical MANNER advantages for the most varied installation spaces and connection requirements with the highest accuracy.

A test bench measuring device for flexible use

Torque acquisition is the central parameter in the development of combustion engines, hybrid and electric modules – and accordingly also on the test benches used for validation.

Since the optimization potentials are getting smaller and smaller, high-precision measuring equipment is necessary to be able to work out these small improvements in a reproducible way. At the same time, the desire for real test conditions (idle, partial and full load, as well as a wide operating temperature range) is high.

The new XtreMA-high precision TORQUE product range from MANNER offers an improved alternative to the torque flanges currently used on test benches.

The DIN flange pattern used, which is compatible with HBM torque sensors, allows simple integration into new and also existing test benches (retrofit). The optional hollow shaft flange design contributes to the flexibility of the XtreMA-high precision TORQUE for use in test benches. This is an immense advantage for coaxial drive concepts, since an additional drive train or additional cables can be routed inside the measuring flange.