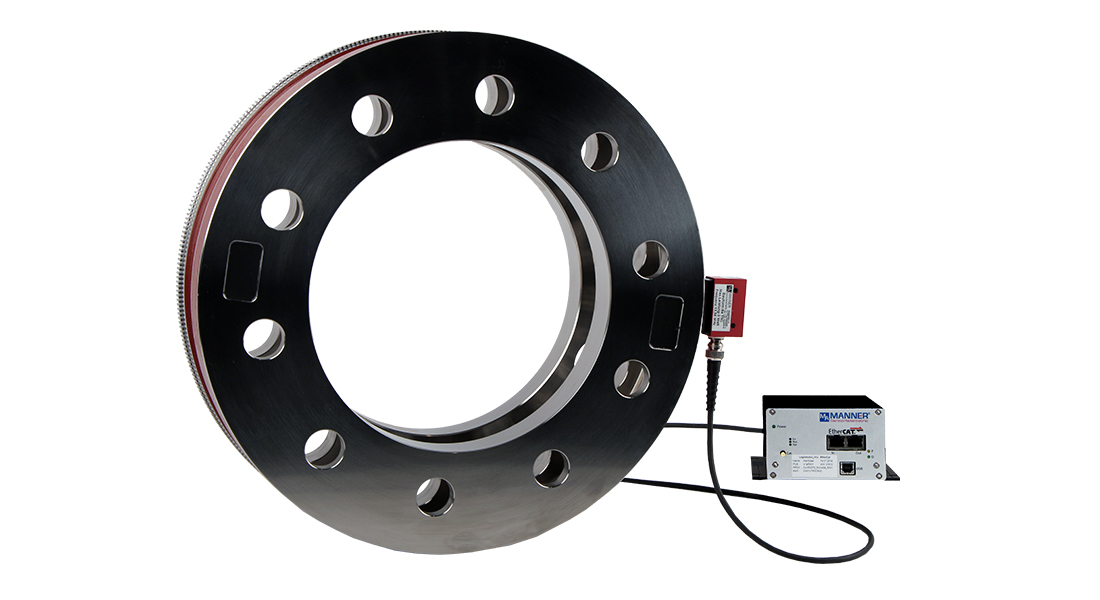

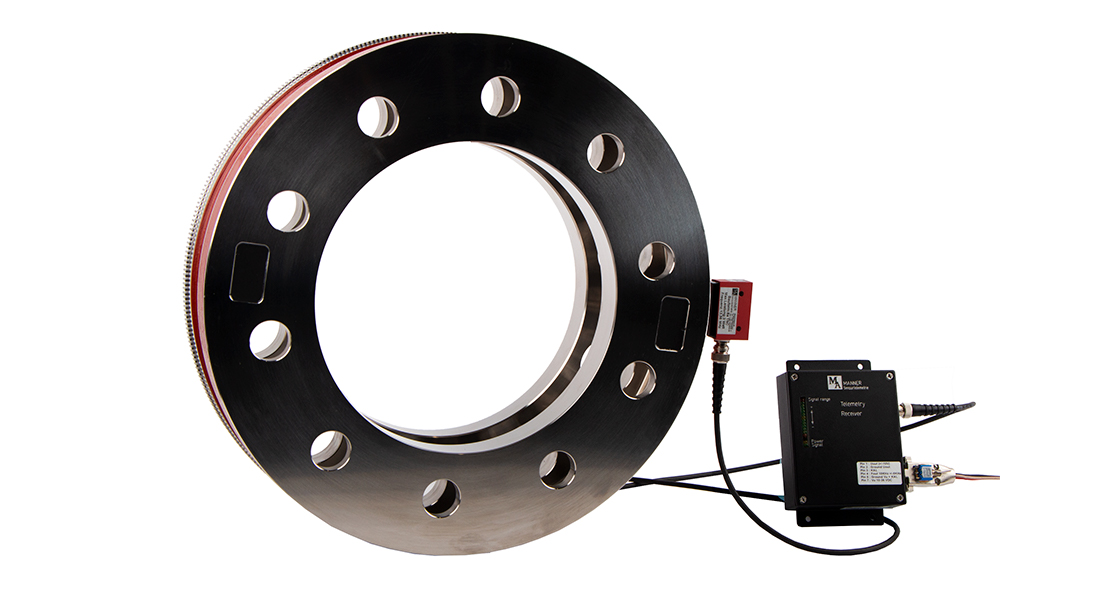

XtreMAX – The torque flange series for power and efficiency increases in large engines, wind power, marine engines as well as gas turbines and much more

Increases in performance and efficiency, also for large engines such as marine engines and construction machinery, are becoming increasingly relevant due to new legal requirements. Representative of this are the requirements for CO2 reductions through environmental agreements such as MARPOL, or the EU exhaust regulations for mobile machinery.

Our solution:

The central parameter for determining the load signal is the torque in conjunction with the speed. For large nominal torques in the field of large engines, wind power, marine engines and gas turbines, we offer the XtreMAX torque flange series. This is an attractive and highly accurate measurement solution for power and efficiency increases, to realize compliance with standards as well as various other measurement tasks.

Maintenance-free operation is a matter of course thanks to the wireless, inductive power supply, which simultaneously realizes a measurement signal pick-up.

Regardless of whether static or high-frequency measurement signals need to be recorded, the system provides the solution.

The standard bandwidth of the measuring signal of 1 kHz can optionally be extended up to 10 kHz. The system is robust against interference fields and can be used anywhere, even close to the electric motor.

The design of the short torque flanges, which has been well proven for years, also offers the possibility of a retrofit. Characteristic for the XtreMAX torque flange series is the compact shape, which at the same time enables a high overload resistance and robustness against parasitic forces such as the bending moment.

The integrated and highly accurate electronics used for data evaluation and transmission of the XtreMAX torque flange series enables the highly accurate recording of the torque including the compensation of temperature influences in the real environment.

By using our digital sensor telemetry, the measurement signals can be recorded from the rotor without any problems. Usual radial distances between rotor and stator of 10 mm and axial displacements of 100 mm can be realized without any problems.

Optionally, speed measurement can also be integrated.

In addition to the compact XtreMAX evaluation unit with integrated pick-up and the classic analogue signals with 0…±10V / 4…20mA and the frequency output 60 +/-30 kHz, the stator unit with remote signal pick-up is also available for installation in the control cabinet. In addition, the output of digital signals via EtherCAT, CAN or Ethernet is also possible here.

The torque series is standard available with the following nominal torques:

15 kN·m, 20 kN·m, 35 kN·m, 50 kN·m, 100 kN·m, 200 kN·m, 300 kN·m, 500 kN·m.

The XtreMAX series, which can thus be used in many areas of application, has proven to be an outstanding solution for years, especially in plant engineering, mechanical engineering, shipbuilding, gas turbines and the construction machinery industry.

Of course, we are also prepared to carry out customized flange pattern adaptations.

Optionally, the system can be manufactured in ATEX design, as well as DAkkS calibrated and acquired with corresponding certificates (e.g. DNVGL, BV, RINA).

XtreMAX flange with different antennas and evaluation units – depending on customer requirements: