Tailor-made inductive non-contact transducers for physical parameters in any assembly situation

MANNER has built up a great amount of know-how over the last 15 years through constant advancement in the design and implementation of specialised transducers for special machine construction such as turbine and turbocharger test benches. The design competence created is ideal for creating high-precision measuring equipment with individual design. This know-how and the new electronic compensation devices of MANNER Sensortelemetrie enable the highly accurate measurement of all physical parameters even at high temperatures of up to 160°C and high speeds of 40,000 rpm.

Motivation – Tough framework conditions

For efficient control and overload prevention, non-contact, highly accurate and maintenance-free measuring equipment is required, not only on the standard test stand.

Especially in special machine construction, retro-fits or new developments, where the space for a standard torque measuring flange was not foreseen by the design or could not be created, tailor-made measuring equipment is required. This also applies to shaft trains with high speeds where the shaft dynamics require rigid drive trains without couplings. In addition, the currently prevailing space-saving concepts represent a further challenge.

Challenge – space is not everything

It is certainly a challenge to design a sensor for specific and limited space conditions. However, there are other challenges to be overcome, such as especially individual connections, as well as the consideration of parasitic forces and possible overloads.

The most frequently measured variable in mechanical engineering is torque. However, this is often accompanied by axial forces and/or a bending moment component. These parasitic forces have a considerable influence on the measuring accuracy. The parasitic forces and torques can be eliminated both by a suitable constructive design and by means of electronic compensation. There are often narrow limits for constructive measures. This often leaves only electronic compensation to create highly accurate measuring equipment.

Unfortunately, the regularly determined measured value deviations at 22 °C (standard room temperature) are dependent on the temperature of the measuring body. The temperature dependence of the E-module changes the characteristic value considerably. The measured value deviation results from temperature fluctuations and is without compensation, approx. 2.5% per 100°C temperature change – thus, for an environmental measuring range of -40°C – +160°C, up to 5% measured value change is realistic with no compensation.

In addition, the measured value deviation at high speeds – especially the zero point – is also dependent on the speed driven. Therefore, this parameter must also be compensated electronically.

In addition to these parameters which have to be actively corrected, overload resistance must also be taken into account in the mechanical design. This is the only way to prevent possible destruction of the torque transducer in case of sudden blockages of the drive train (e.g. due to bearing damage).

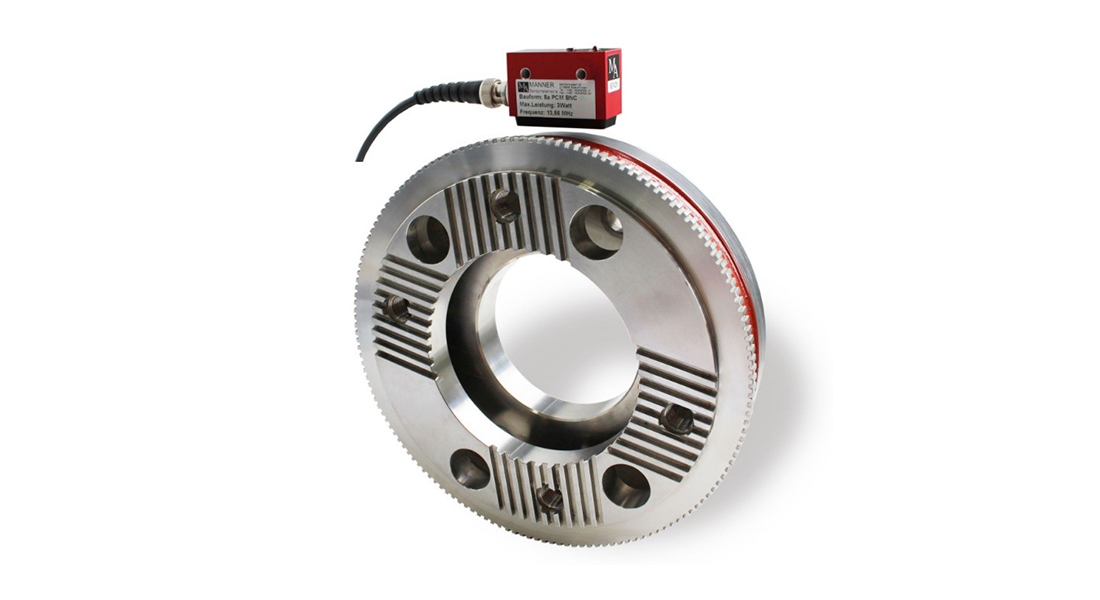

High-precision, maintenance and wear-free measuring sensors in tailor-made design

In addition to the standard torque series XtreMA (HBM- T40 compatible), MANNER offers customized flange geometries for these applications.

This enables both individual physical variables (torque, axial force, bending moment) and several in one transducer to be measured contactlessly and maintenance-free by means of inductive sensor telemetry.

Within the scope of a project design, your requirements such as flange pattern, installation space, temperature and force inputs are recorded and a customer-specific mechanical design is developed based on years of experience.

We have developed a new real-time compensation module for highest accuracy, even under massive temperature input, remaining parasitic forces and speeds. This innovative module allows almost complete compensation of the temperature influence on the zero point and characteristic value. These are caused, for example, by E-module changes above temperature and the shift of the zero point. Due to the novel, non-linear compensation, the accuracy of the measuring flange remains constant over the entire temperature range.

If desired, the measuring sensor can be integrated into a speed recording in addition to the physical variables.

The inductive transmission method with a range of up to 40mm allows all measured variables and the speed to be recorded conveniently. Even in case of vibrations at the drive train, this distance ensures the integrity of the measuring device.

The measurement data can be transferred to the data acquisition system as a classic analogue signal, e.g. voltage, current or frequency, or as a digital signal via EtherCAT, Ethernet or CAN interface. The contactless, inductive sensor telemetry transmission technology guarantees maintenance-free operation.

Challenges in measurement technology have been our passion for 30 years – feel free to ask us for your problem solving!

Some examples of our designs