Turbines are among the most powerful machines of all. The mechanically usable power of turbines, which can amount to an incredible 1.5 gigawatts, is obtained via the turbine blades and finally delivered to coupled machines via turbine shafts, where the highest speeds dominate. Knowing the load on the blades, especially when vibrations are excited, is of enormous importance for qualification. The same applies to thermal loading. MANNER measuring technology allows these variables to be recorded dynamically and the operational stability of the turbine to be derived from the data. Our measuring systems are used in this extreme and challenging environment where, among other things, accuracy, robustness and temperature stability are required.

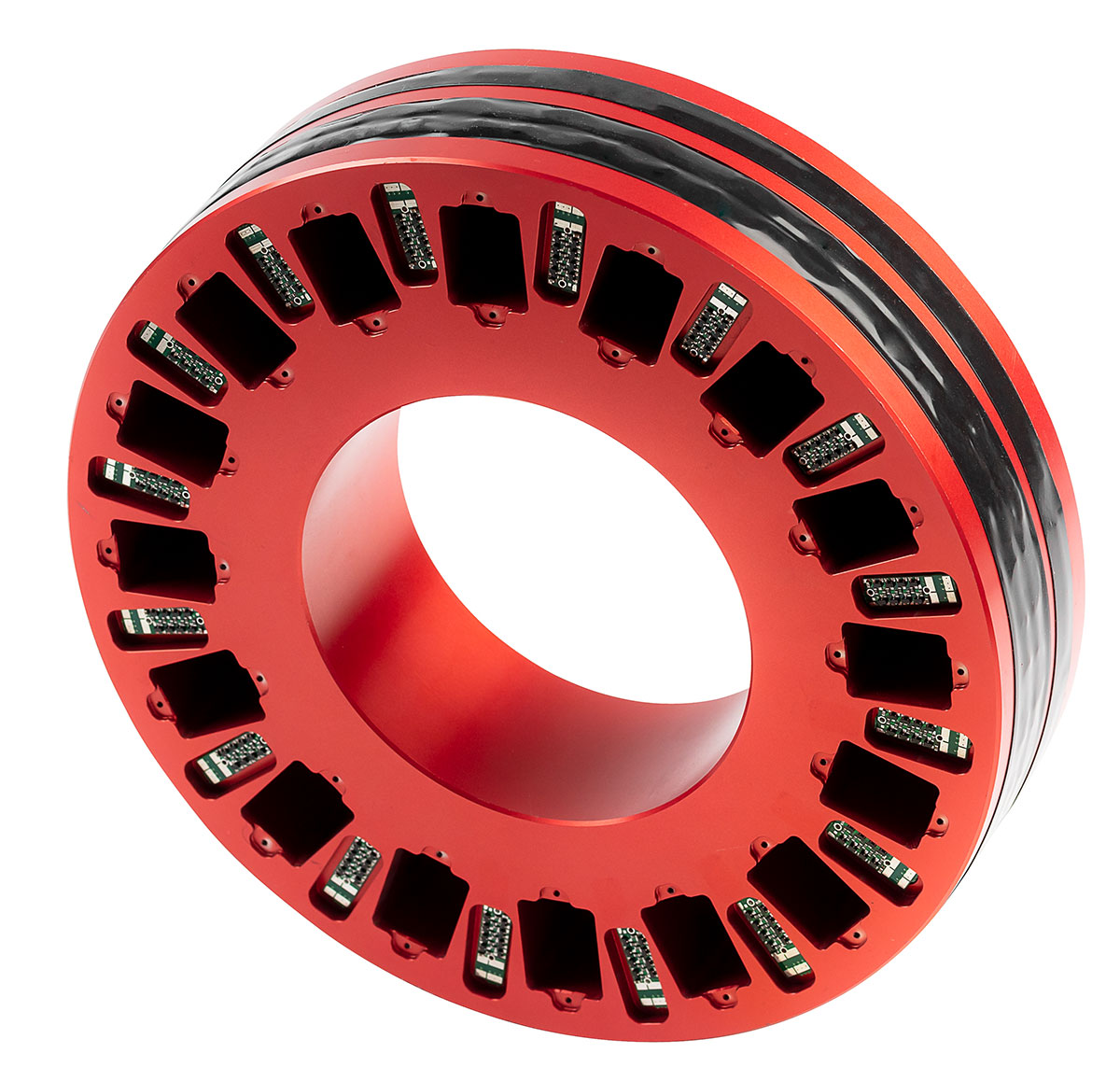

MANNER Sensortelemetrie GmbH has been proving its know-how in the challenging measurement application of single or multi-shaft turbine machines for many years.

With the help of our non-contact sensor telemetry, the thermal load on the turbine blades can be determined just as easily and precisely as the rotational speed or blade vibrations. In this way, material fatigue on the blades can be avoided, thus preventing fatal damage, while the simple collection of measurement data is guaranteed by specially programmed telemetry software.