Bearingless torque measuring shaft for small torques – speed-resistant, robust, maintenance-free and trouble-free with high accuracy

As an engineering and manufacturing company, MANNER Sensortelemetrie has been offering sensor telemetry for non-contact measurement on rotating transducers for 3 decades.

Our standard torque measuring shafts are bearingless and, compared to the classic slip ring torque measuring shaft, measure torques in the drive train without wear and force shunt. Even the highest speeds of up to 160.000 rpm are possible – without disturbing noise from bearings.

Especially when it comes to accuracy, the bearingless shaft still has clear advantages over a measuring shaft with bearings. The basic accuracy of MANNER measuring shafts is better than 0.05 %. In addition, further compensation options can be optionally integrated to eliminate influences such as the modulus of elasticity on the torque.

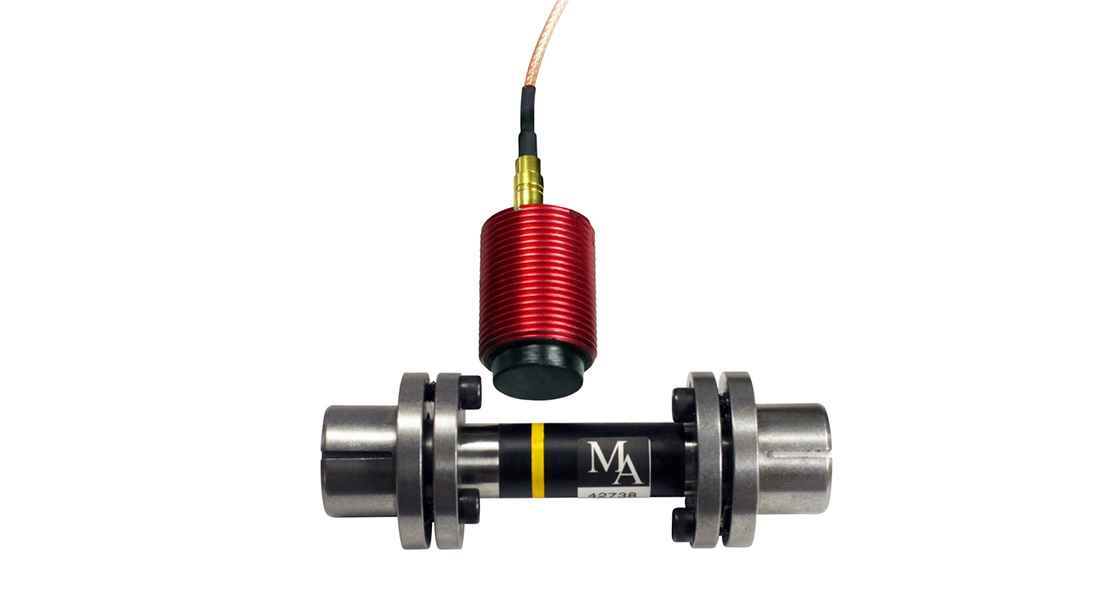

Other characteristic features are the extremely low moment of inertia and the simple integration into the shaft train. In the standard version, this can be done using cost-effective Lenze clamping couplings. This eliminates the need for complex bearings and simplifies the construction of test benches, which in turn saves costs.

The MANNER torque measuring shaft thus offers enormous advantages for test bench measuring tasks. Today we would like to introduce you to two types of design, our standard and customised test stand shafts for particularly small torques.

In the standard range we have measuring shafts from 1N-m to 1kN-m with an extremely small moment of inertia and high speed stability. Here, the integration into the shaft train is done by low-cost Lenze clamping couplings or via bellows couplings.

Optionally, a speed measurement with high resolution can be integrated into the measuring shafts. In another standard variant, the torque is transmitted at both shaft ends via a feather key. The basic accuracy of our measuring shafts is 0.05% in relation to the measuring range end value and, depending on the version, they can be used up to 156,000 rpm and in a temperature range from -40°C to +160°C.

Some examples of the standard design for small torques:

Figure 1: Standard measuring shafts with clamping couplings

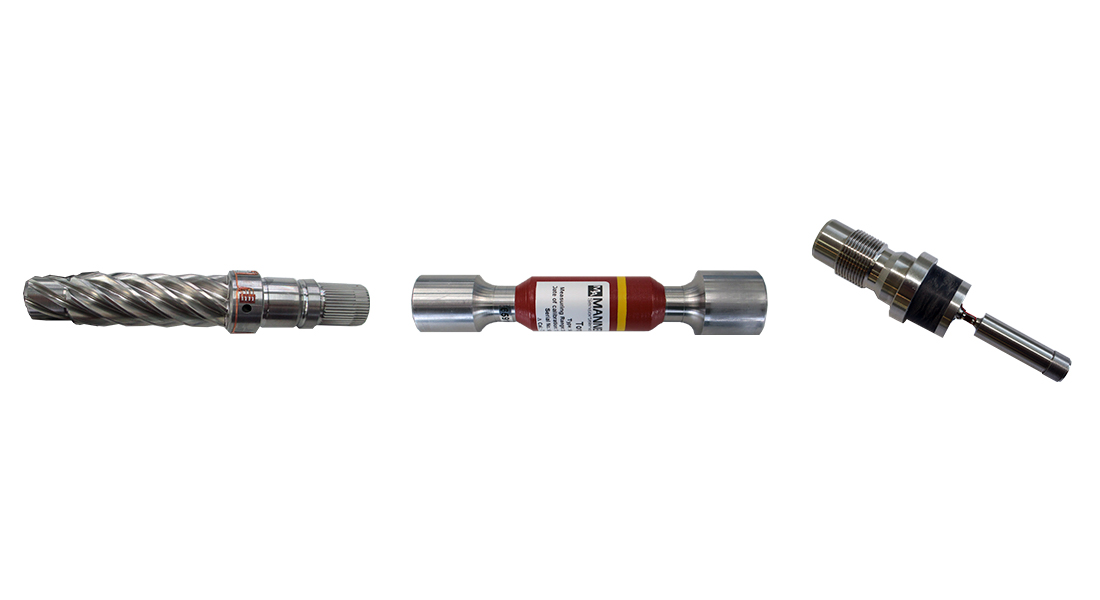

Figure 2: Standard measuring shaft with optical speed detection and feather key connection

Figure 3: Standard measuring shafts of different sizes and feather key connection

If the integration of a standard measuring shaft is not possible, our customised measuring shafts can be used. The construction, design of the measuring point and manufacture of the measuring shaft is carried out in-house. With this solution, complex and for the measurement unfavourable embeddings in the shaft train can be avoided.

Some examples on our production clearly show that there are no limits to our innovation and creativity as an engineering company in order to realise the customer’s request with the corresponding accuracies:

Figure 4+5: Customised measuring wave solutions

Figure 6: Customised turbocharger test rig shaft (0.2N-m/150,000 rpm max)

Our technology:

Our transducers work inductively with our patented transmission method. High data rates are securely transmitted inductively – even in the presence of interference fields that frequently occur nowadays – from e-motors. In addition to this robustness, temperatures of -40°C – +160°C and environmental parameters such as oil are no challenge at all. Development, transducer design and production are all carried out from a single source.

Thus, MANNER offers torque measuring shafts for the highest requirements.

The torque signal is obtained by means of the proven strain gauge technology. A highly accurate, digital and remotely programmable measuring amplifier on the shaft amplifies, conditions and digitises the measured value with 16-bit resolution. The speed is recorded by means of a Hall sensor or a laser sensor, which allows large distances between the measuring shaft and the speed sensor. The torque and speed data can be transmitted via analogue (frequency, voltage or current output) or digital via CAN, EtherCAT, Ethernet or USB. The contactless transmission is characterised by an antenna gap of up to 10mm (optionally 25mm). This makes installation absolutely unproblematic, even in radial and axial directions, and collisions due to vibrations are practically non-existent.