Innovative Precision Torque Measurement for Rally Sport Using Radio Telemetry Systems: Precise Torque Measurement Under Extreme Conditions!

Whether in motorsport for endurance races or off-road competitions – from Le Mans to the Dakar Rally: MANNER Sensor Telemetry is the leading partner for high-precision measurement technology in extreme operating environments. With decades of experience as a market leader in the field of sensor telemetry, we offer powerful solutions to capture precise measurement data even under the toughest conditions, both through inductive, maintenance-free telemetry and radio telemetry.

The solution can also be advantageously used for short benchmark tests.

Today, we are reporting on a particularly exciting practical example!

Challenge: High-Precision Torque Measurement in the Shortest Time

Just before Christmas, a British racing team urgently contacted us with a request. The goal was to equip four side shafts of an off-road race car with a custom dynamic torque measurement system and radio telemetry within a week. Due to the extreme requirements in the vehicle’s operation, the team opted for our state-of-the-art radio telemetry system, which was specifically developed and tested for use under the harshest conditions.

Why Radio Telemetry?

The decision to choose a next-generation radio system over an inductive system was based on several factors:

1. Extreme Suspension and Off-Road Conditions

The significant suspension travel of the vehicle posed a challenge for mounting an inductive rotor loop. The radial movements of the drive shafts of over 150 mm, combined with heavy stone impacts and high mechanical loads, required precise structural adjustment to ensure stable signal transmission – a process that could only have been realized with significant effort within a week.

2. Quick Implementation in Just One Week

Due to performance issues, the power flow of the race car had to be accurately measured. Since the racing team was under tight scheduling pressure, the measurement system had to be operational within a few days. Any delay would have incurred significant costs.

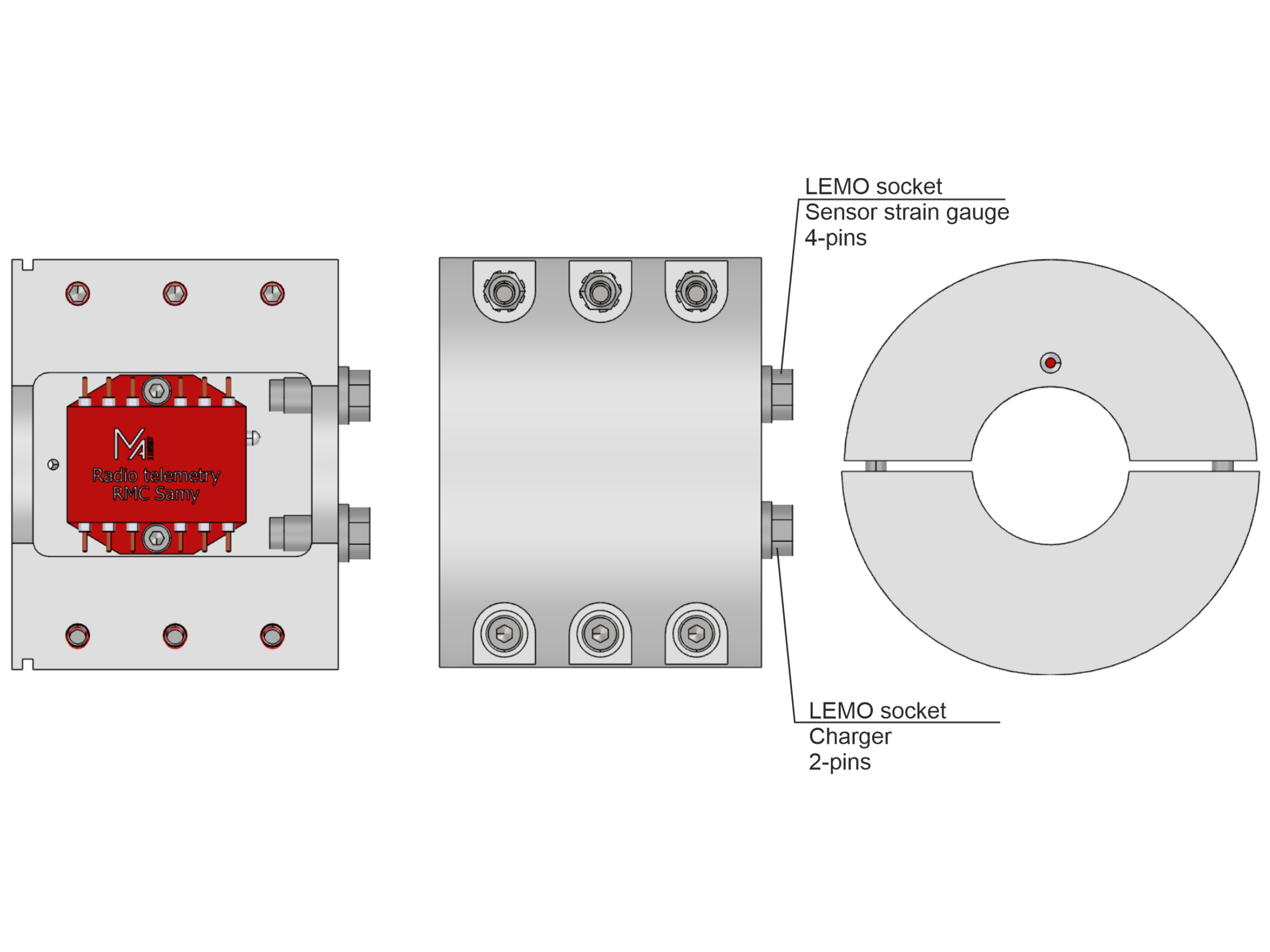

Thanks to MANNER’s high-strength 3D printing, the half-shells for the rotor transmitter and the batteries with charging ports were produced overnight. Within just five working days, the entire system was ready for shipment – a fast and reliable solution to optimally support the customer in this critical situation.

3. Measurement Duration of Up to 50 Hours

The system is flexible in terms of measurement duration and can be adjusted according to the requirements. In this case, a runtime of 50 hours was chosen to keep the battery size compact, as 50 hours was more than sufficient for the planned training days. The rotor sensor is controlled remotely, eliminating the need for manual deactivation directly under the vehicle. This feature is particularly advantageous in off-road use, where the vehicle is often heavily dirty after runs, as no mechanic needs to go under the vehicle to turn off the sensor. Furthermore, the transmitter can only be activated remotely during actual measurement operations.

MANNER offers three options for controlling the rotor transmitter:

· Switch on the evaluation unit

· Software control via USB connection from the evaluation unit or via CAN

· MANNER App for smartphones or tablets

4. Easy Rechargeability and High Durability

Since the system may be used for multiple measurements, an uncomplicated rechargeability through a connector was ensured. At the same time, it had to withstand extreme off-road conditions such as stone impacts and water exposure. Waterproof plug-and-play charging ports were integrated to ensure seamless handling.

5. User-Friendliness: Plug & Play for Quick Deployment

The system was designed to be deployed quickly and accurately by non-specialized personnel. The measurement shafts were fully waterproofed by MANNER. The delivery package included:

• Ready-to-use measurement shafts with integrated radio telemetry

• Charger with the appropriate connector for the side shaft socket

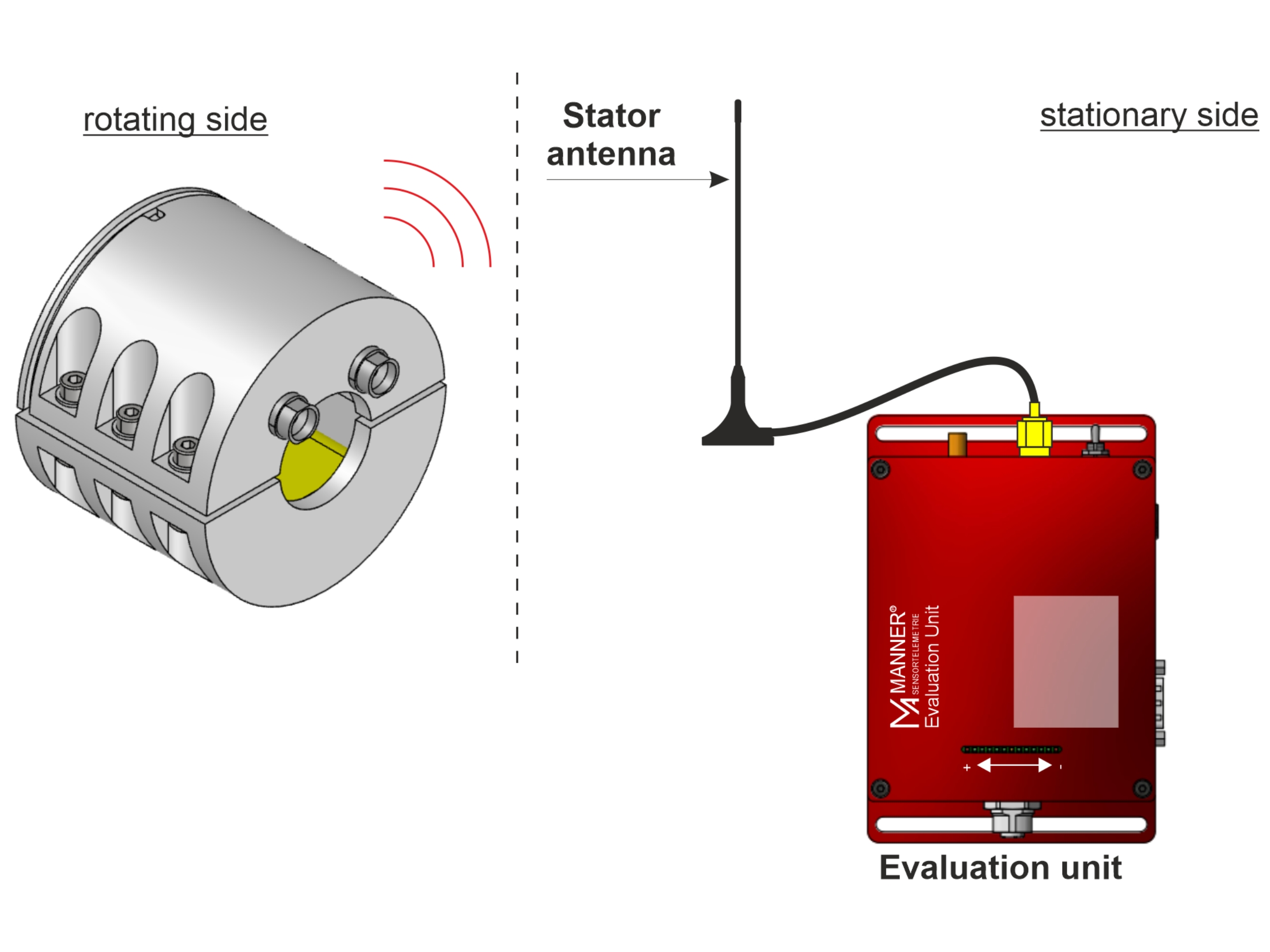

• Flexibly positioned stator antenna for data transmission

Additionally, the MANNER software or MANNER app allows for easy monitoring of the battery status – so the number of uses that can still be done with the current battery charge can be estimated at any time.

The system itself consists of the strain gauge for torque measurement, the sensor signal amplifier, and the OptiMA evaluation unit. Depending on the installation environment, the desired sensor signal amplifier can be flexibly chosen as an end-of-shaft version or applied on the shaft with a rotor antenna kit.

6. Flexibility in Measurement Data Output

As is common in professional vehicle applications, CAN data transmission is provided. Alternatively, an analog voltage output is available. The MANNER evaluation unit offers the highest flexibility by outputting various signals (voltage, current, frequency, CAN, Ethernet, EtherCAT, etc.) depending on customer requirements. Integration into existing data logger systems is also easily possible.

Conclusion: High-Performance Measurement Technology for Motorsports

Thanks to innovative technology, fast production, and a customized solution, MANNER Sensor Telemetry was able to offer the racing team a powerful, reliable, and immediately deployable measurement solution. The combination of robust construction, ease of use, and flexible data output makes the system the perfect choice for demanding motorsport applications – from Le Mans to Dakar.

MANNER – Precision in Motion.