Professional solutions for measurements on hybrid vehicle power trains

In addition to the fully electric car for city driving, the development of far more complex hybrid vehicles is being aggressively pursued.

Important issues for the development of hybrid vehicles include the load spectra for system design, fatigue limit design, and the optimised handling on the road. In particular the optimal interaction between the combustion engine and the electric motor represent an enormous challenge for the control equipment.

For designing the algorithms, the dynamic torque behaviour in the power train at various points is crucial. Important measuring points include the interfaces between combustion engine and electric motor, gearbox input, gearbox output, front drive output, and axle shafts. For partial load measurements in particular, high demands are placed on the precision of the torque measurement. The measuring points between combustion engine, electric motor, and electric motor gearbox input are subject to particularly high thermal loads. As a rule, a temperature range from – 40 to +160 °C needs to be covered. In addition, there is the oil environment. High precision for test stand torque sensors at near-constant ambient temperature in an oil-free environment are state-of-the-art today.

Things become more interesting if similar accuracy is sought at ambient temperatures between -40 and +160°C in the power train section between gearbox and combustion engine. This requires corrections not just for the effect of the temperature on the telemetry but also for its effect on the torque measuring point (changed material properties: zero point and changed elastic modulus). The corresponding corrective features in the MANNER sensor telemetry equipment provide for consistent accuracy, regardless of the component temperature. Picking up the torque on the axle shafts is relatively easy.

Of course, the measurements at all torque measuring points must be absolutely synchronous. Otherwise, no power flow analyses can be performed. In addition, the telemetry transmission must be without drop-outs (missing data caused by telemetry transmission errors). In combination with the high EMC loading of electric motors, systems using radio transmission are particularly vulnerable. A great many real-life measurement uses have demonstrated that the MANNER sensor telemetry components are absolutely robust when faced with any kind of interference. MANNER systems are synchronised, provide data in real time (latency between detection on the shaft and playback is < 0.5 ms), and are without any telemetry transmission errors.

Whenever measuring points are required in the gearbox, clutch, or electric motor, the space requirements are tricky. It is difficult to find adequate space for the telemetry equipment. This is where our high-temperature resistant Flex telemetry equipment comes in handy; it has a width of 10 mm and a height of 3 mm and can be wound around the shaft. It makes it possible to set up high-precision torque measuring points in the most confined spaces.

Figure 1: Gearbox input shaft with Flex sensor signal amplifier, sensor, and antenna

A closer look at some solutions:

Revolutionising the telemetry range: Axle shaft applications with MANNER – just plug&play

Special emphasis must be placed on the measuring equipment on the axle shafts. The axle shaft is the dynamic connection between the gearbox and the drive wheels via the constant-velocity joints. It is characterised by its large displacement when the vehicle is driving. This requires a corresponding long telemetry transmission range. The systems must be maintenance-free and without batteries.

In real-life use, the system version with the stator loop antenna has proven to be the optimal solution. The rotor antenna placed around the axle shaft and the loop-type stator antenna act like a transformer that transmits both the torque data and the power supply.

The range of the advanced version developed by MANNER is 2.5 times greater, which allows for an extremely high installation tolerance. This improvement is not based on more energy for the induction field but on technological innovation. The plug & play solution can tolerate small installation errors. And the current consumption is significantly lower, compared to other systems.

Figure 2: Installed axle shaft with flexible stator antenna

Miniature thermocouple elements combined with measuring equipment: Thermal validation of clutch plates

Another important component is the clutch that is used for connecting and disconnecting the combustion engine and the electric motor. Because of the high power density and the low unit volume, wet clutches are used today.

However, the high power density places high demands on the clutch plates. The thermal validation of the plates represents a particular challenge for the measuring equipment. The reliable detection of the dynamic temperature behaviour in the friction linings depending on load and oil pressure requires a lot of know-how. Building thermocouple elements into the friction linings with a thickness of just 0.8 mm requires excellent craftsmanship. Typically, up to 16 measuring points are installed. In addition, the plates move horizontally in quick sequence at high speeds. . The desired long service life of all 16 measuring points places enormous demands on the wiring, which needs to withstand very high speeds. For this type of challenge, MANNER has many years of experience that guarantee successful measurements. Of course, the measuring signals must also be transmitted to the stationary part. Accordingly, cascading 8-channel miniature telemetry modules (size 12 x 21 x 5 mm) with a temperature resistance of 180°C guarantee the reliable transmission of the temperature values in an oil environment.

Figure 3: Clutch with 16 temperature measurement channels

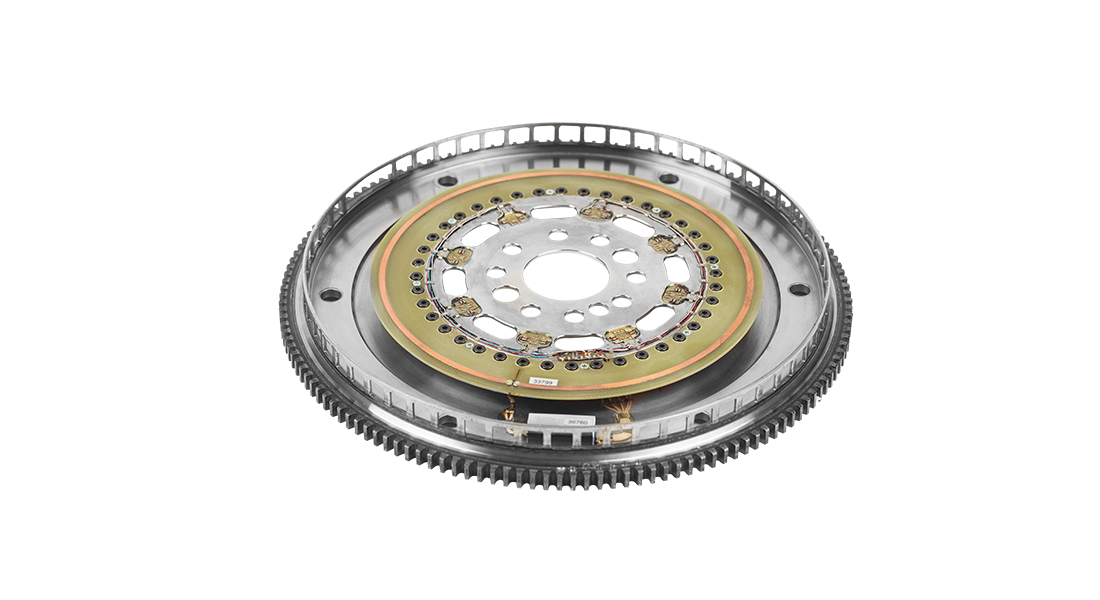

Reliable dynamic torque despite parasitic forces: Flexplate torque sensors at the core of the drive train

MANNER has developed a special technique for refining series flexplates to create high-quality torque sensors for vehicles with an accuracy class of 0.05%.

The sensor does not require an extension of the drive train and it does not affect the drive train’s dynamic properties. Its centrepiece is a specially designed sensor with extremely low crosstalk behaviour when faced with axial, bending, and lateral force loads. To ensure accuracy over a wide temperature range (-40°C to +160°C), compensation is performed for zero-point drift and elastic modulus. The latter is done electronically with the aid of an additional temperature measurement channel and mechanical calibration with temperature. The new feature is a digital signal processor that corrects the detected torque in real time using the identified error polynomial. The result is a torque signal that is virtually independent of any temperature effects and that can be evaluated immediately.

Figure 4: Flexplate sensor with temperature resistance of 160°C for capturing dynamic torque

The high time resolution of the torque signal at 4000 measured values per second guarantees a true representation of the torque curve. This means that, for the first time, dynamic high-precision power flow measurements can be performed on the drive train. This tool is ideally suited to the optimisation of drive train components. The measured data from the strain-gauge transducer are transmitted contactless by MANNER’s tried-and-tested digital sensor telemetry equipment with 16-bit resolution.