WiFi-Wellentelemetrie mit Smart Interface

Plug & Play telemetry with customised 3D printing – inhouse production or from MANNER

Non-contact measurement data transmission in real operation under harsh environments is still a challenge today. The construction of an inductive maintenance-free and endurance-proof telemetry transmission is costly and justified for long-term measurements. But there are also short-term measurement tasks. Here there is a desire for the least amount of assembly.

In order to create a solution for this measurement task profile, MANNER wireless sensor telemetry was developed. The focus was also on designing a wireless telemetry system that masters measuring tasks with increased environmental requirements. In addition to its resistance to disturbances, it is also resistant to temperature, water and vibration.

As is well known, the radio telemetry system powered by rechargeable batteries is characterised by the simplest handling, as the assembly of pick-up and rotor induction loop is no longer necessary. In addition, today’s lithium-ion batteries have significantly more capacity. This means that the available operating time between charging processes is significantly longer.

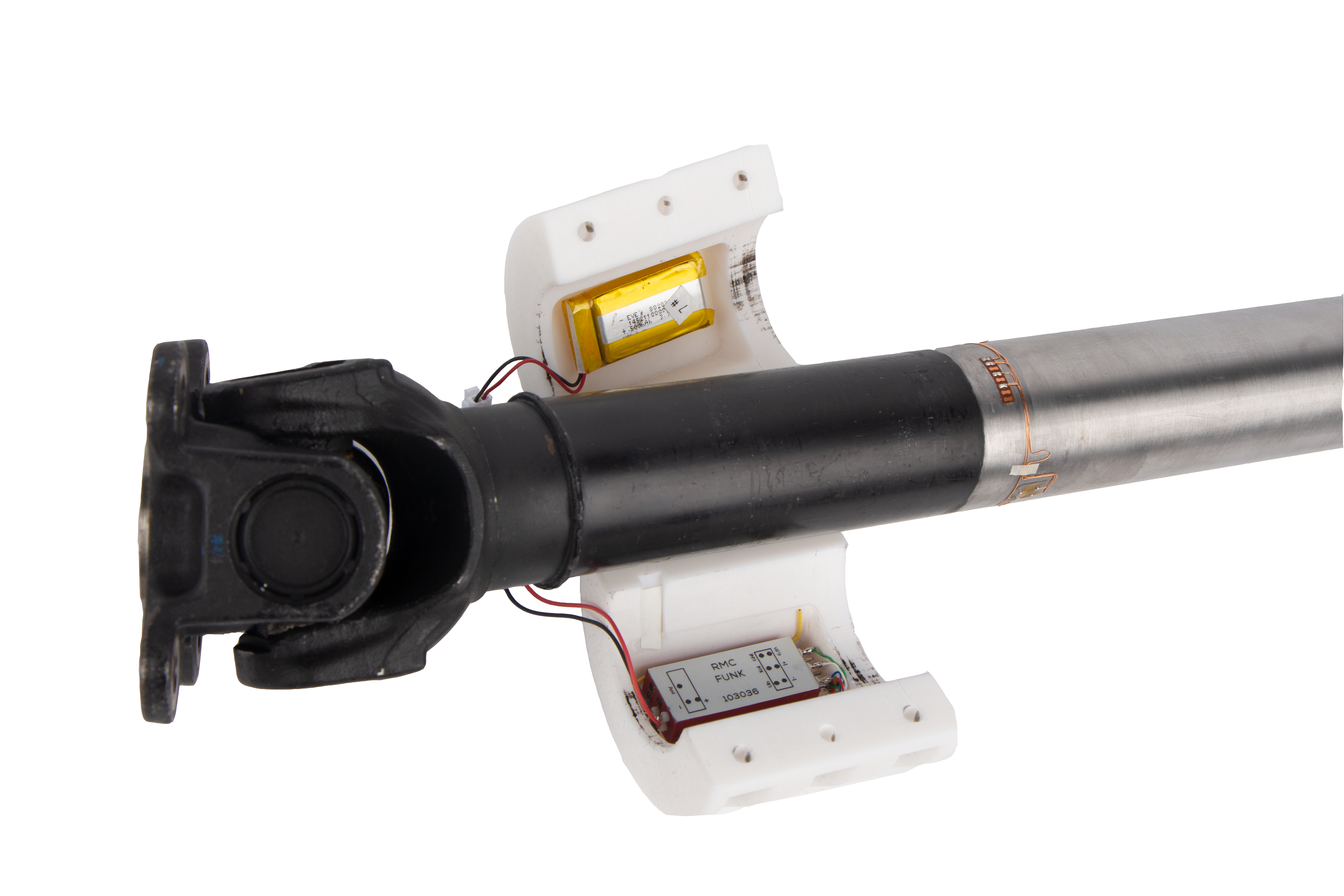

In addition, 3D printing technology can be used to produce dimensionally accurate half shells for mounting on the side shafts or cardan shafts in a very short time.

Corresponding 3D basic designs are available from MANNER. These designs can be adapted to the customer’s shaft in the shortest possible time by the customer himself or by MANNER.

Printing can be carried out by the customer or by MANNER with a delivery time of less than 3 days.

The measuring amplifier with radio cell for direct connection of strain gauges, thermocouples or other sensors and the battery are simply inserted. The half shells are then screwed together.

Figure 1: Side shaft with radio telemetry from 3D printing

Thus, the product can be reused quickly and flexibly for different measuring tasks due to its robustness.

To further simplify initial set-up, MANNER combines wireless telemetry with the new Smart Interface for smartphones and tablets. This way, the status of the telemetry, the configuration of the measuring range including the battery status can be conveniently checked via smartphone. The complete setup of the measuring amplifier (measuring range, autozero, etc.) is also set via the Smart Interface.

The power-saving technology allows a measurement time of up to 1000 hours for temperature measurement tasks and 32 hours for dynamic measurement tasks without recharging or replacing the battery.

The sensor telemetry can be waterproof and also oil-resistant. The temperature resistance from -35 to +120°C should also be emphasised.

Another advantage of the telemetry is the possibility to use several systems in parallel and to change the transmission frequencies depending on the place of application (433 MHz standard). The flexibility of data output and transmission should also be emphasised. With the MANNER evaluation unit, the signal can be sent out in any analogue (voltage, etc.) or digital signal (CAN, WLAN, etc.) format.

Conditioning of the measuring amplifier (zero point and gain setting) is easily possible during operation using the Smart Interface App. This avoids possible test repetitions due to incorrect settings and repeated effort.

Figure 2: Simple sensor check and settings via the app

Also available as multi-channel with high sampling rates

Flexibly configurable, the system is available in 1/2 channel or also for up to 16 channels. Each channel has its own AD converter and power supply. If a sensor is short-circuited, there is no reaction on the remaining measuring channels. This means that even complex rim measuring tasks with up to 16 measuring channels can be mastered.

The measured values are already digitised at the rotating measuring point, e.g. vehicle wheel with 16 bits, and then transmitted by radio in time multiplex to the particularly compact receivers. Multi-channel signal bandwidths of up to 40 kHz can also be realised. The integrated data backup detects sporadic transmission interferences and completely hides them.

Through additional antenna diversity (several reception channels, selection of the best signal), extremely high transmission reliability can be guaranteed. Faulty measurement data is therefore not possible. The incoming signals are just perfect and free of errors.

Figure 3: Receiver

Dual-use also possible

On request, the new MANNER system is also available as dual-use. Of course, the system can be powered inductively as well. On the one hand for short-term measuring tasks using a rechargeable battery, on the other hand for long-term measurements with inductive supply with unlimited runtime.

This means that a short-term measuring point originally operated with a rechargeable battery can also be subsequently converted into a long-term measuring point with inductive supply.

This capability greatly simplifies the service for measurement service providers for logistics and maintenance. The system is compact, lightweight and ideal for air travel. It fits into any service box.

Together with the MANNER acquisition software, this provides a laptop-based, compact and cost-effective data acquisition system with visualisation and evaluation options.